Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

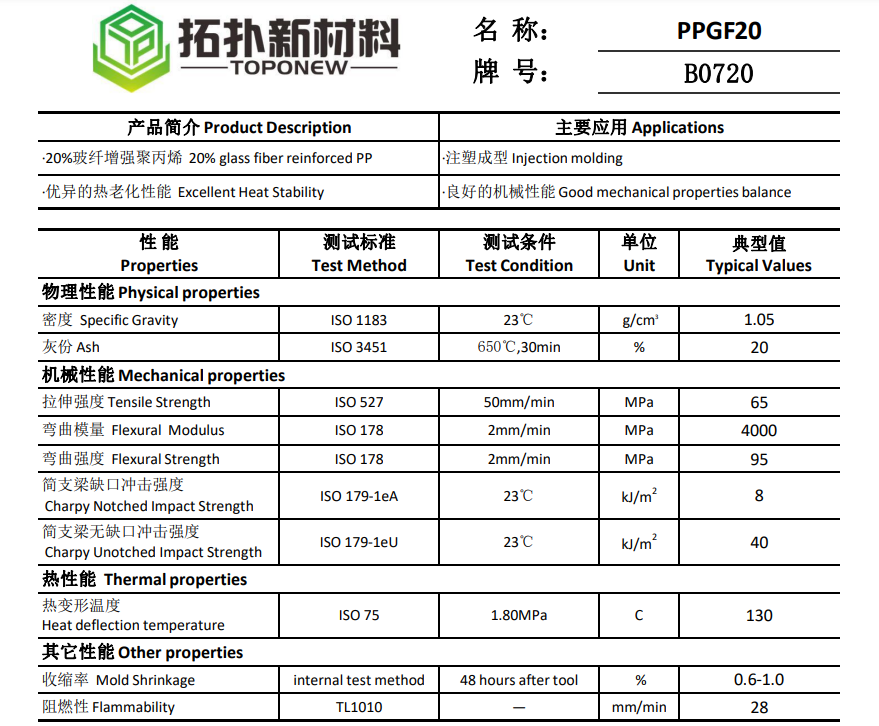

PP GF20 B0720

Glass Filled: 20%

(Custom materials available according to your Technical Data Sheet)

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PP GF20 B0720

Introducing our latest innovation - PP GF20 B0720, a unique blend of PP granules infused with 20% glass fiber for enhanced performance and durability! Dive into the world of glass-filled PP material, where strength meets versatility. Discover the exceptional properties of this composite, combining the lightweight nature of polypropylene with the added strength and rigidity from glass fiber reinforcement.

Unlock a world of possibilities with PP GF20 as it finds its application in a wide range of industries, from automotive parts to electronic components, where high strength and chemical resistance are paramount. Whether it's for injection molding, extrusion, or blow molding, this material is engineered to elevate your projects to new heights.

Excited to explore the potential of PP GF20? Contact us today to learn more about polypropylene pellets price and PP natural granules price, and take the first step towards innovative and sustainable solutions for your manufacturing needs.

What is PP GF20?

PP GF20 stands for Polypropylene (PP) with 20% Glass Fiber reinforcement. It is a composite material where polypropylene is mixed with 20% glass fibers to enhance its mechanical properties. The addition of glass fibers improves the strength, stiffness, and heat resistance of the polypropylene, making it a suitable material for applications that require increased performance compared to standard PP.

PP GF20 is commonly used in industries such as automotive, electronics, consumer goods, and industrial manufacturing where a balance between strength, rigidity, and cost-effectiveness is needed. It offers improved dimensional stability and heat resistance compared to regular PP, making it a popular choice for various engineering applications.

Glass Fiber Reinforced Polypropylene (PP GF) combines the properties of polypropylene with the enhanced mechanical characteristics provided by the addition of glass fibers. Some of the key properties of glass fiber reinforced polypropylene include:

-

Mechanical Strength: The addition of glass fibers significantly improves the tensile strength, flexural strength, and impact resistance of polypropylene, making it stronger and more rigid.

-

Stiffness: PP GF exhibits increased stiffness and dimensional stability due to the presence of glass fibers, making it more suitable for applications requiring structural rigidity.

-

Heat Resistance: Glass fiber reinforcement enhances the heat resistance of polypropylene, allowing it to withstand higher temperatures compared to pure polypropylene.

-

Chemical Resistance: Polypropylene itself offers good chemical resistance, and the addition of glass fibers does not significantly alter this property, making PP GF suitable for various chemical environments.

-

Lightweight: Despite the reinforcement with glass fibers, PP GF remains relatively lightweight compared to other materials with similar mechanical properties.

-

Creep Resistance: The addition of glass fibers can improve the creep resistance of polypropylene, making it more resistant to deformation under constant load over time.

-

Electrical Insulation: Glass fiber reinforced polypropylene can maintain good electrical insulation properties, making it suitable for electrical and electronic applications.

-

Cost-Effectiveness: PP GF offers a good balance between performance and cost, making it a popular choice for applications where enhanced mechanical properties are required without significantly increasing the material cost.

Overall, glass fiber reinforced polypropylene is a versatile material used in a wide range of industries for applications requiring a combination of strength, stiffness, heat resistance, and durability.

Glass-filled polypropylene, such as PP GF20 or PP GF30, offers several benefits over traditional unfilled polypropylene. Some of the key advantages of glass-filled polypropylene include:

-

Enhanced Mechanical Properties: The addition of glass fibers improves the tensile strength, flexural strength, impact resistance, and stiffness of polypropylene, making it stronger and more durable.

-

Dimensional Stability: Glass-filled polypropylene exhibits better dimensional stability under varying temperature and load conditions, making it suitable for applications where precise dimensions are critical.

-

Improved Heat Resistance: Glass fiber reinforcement enhances the heat resistance of polypropylene, allowing it to withstand higher operating temperatures compared to unfilled polypropylene.

-

Reduced Warping and Shrinkage: The presence of glass fibers in polypropylene helps minimize warping and shrinkage during processing and use, ensuring better part quality and performance.

-

Lightweight: Despite the added strength and rigidity, glass-filled polypropylene remains relatively lightweight, offering a good balance between performance and weight.

-

Cost-Effectiveness: Glass-filled polypropylene provides enhanced mechanical properties at a relatively low cost compared to other engineering plastics, making it a cost-effective choice for many applications.

-

Design Flexibility: The improved mechanical properties of glass-filled polypropylene allow for more design freedom and creativity in engineering applications, enabling the production of complex and lightweight parts.

-

Chemical Resistance: Polypropylene inherently offers good chemical resistance, and the addition of glass fibers does not compromise this property, making glass-filled polypropylene suitable for various chemical environments.

Overall, glass-filled polypropylene is a versatile material that combines the benefits of polypropylene with enhanced mechanical properties, making it a popular choice for a wide range of applications across industries such as automotive, electronics, consumer goods, and industrial manufacturing.